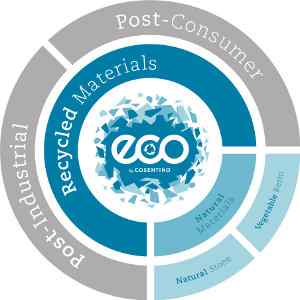

Many years of comprehensive research and development have gone into a surface that has been engineered to be a state-of-the-art product that embraces sustainability. Eco countertops are a highly sustainable, ecological alternative to similar countertops. They reuse waste products to make sensible use of natural resources that would normally go to waste. Eco countertops are manufactured from 75% recycled materials (25% is a blend of quartz, natural stone, pigments and vegetable resin) and still maintain the design and quality that people expect from Silestone. Throughout the manufacturing process, even 94% of the water is re-used in conjunction with recycled materials:

- Porcelain from tiles, sinks, toilets, and other similar products

- Glass, windows, containers and glassware

- Mirrors from dwellings, buildings and factories

- Earthenware from reclaimed tiles

- Vitrified ash and waste from blast furnaces and power generation

Eco Countertops boast that they are at the forefront of a new era where ecological awareness, environmental respect, and sustainability all play a crucial role… where life demands responsible consumption, an awareness of one’s environmental impact, and a goal of improving our quality of life. The first step is in the manufacturing processes where recycling is an essential step towards achieving a more efficient use of our resources.

Eco Countertops Production Process

- The raw materials are supplied by commercial organizations that specialize in waste management. These materials undergo a thorough cleaning, filtering, and grading process.

- The materials are then poured into a mixer and combined with exclusive environment resin.

- When the mixture has melted, it is spread onto a large conveyor belt and compressed.

- The compressed product is treated in an industrial oven for 1 hours and allowed to cool for a day.

- The slab is calibrated and polished with diamond buffing pads to create the finished product.

Advantages of Eco Countertops

♦ Reduces landfill waste

♦ Saves energy by not using new raw materials

♦ Re-uses of obsolete and discarded items

♦ Reduces consumption of natural resources

♦ Reduces water usage – recycles 94% of water used

♦ Reduces emissions throughout manufacturing

♦ Filters 99% of Volatile Organic Compounds (VOCs)

♦ Uses no solvents in machinery cleaning and maintenance

♦ Uses advanced filtering systems

♦ Re-uses every product